Mining giant Rio Tinto and premium automotive brand BMW will partner to produce cars using zero-carbon aluminium.

A recently announced Memorandum of Understanding (MoU) between the two companies will rely on ELYSIS smelting technology developed in a JV between Rio and Alcoa. The cutting-edge technology is the first smelting process of its kind and can produce zero-carbon aluminium with pure oxygen as its only byproduct.

BMW hopes to achieve a carbon saving of 70% by switching to clean aluminium.

Ore for Rio’s low-carbon aluminium is currently sourced from its hydro-powered operations in Canada before getting mixed with recycled materials. The British miner is looking to the automotive industry to find new partners and, ultimately, buyers for its clean aluminium product.

The BMW deal marks a significant milestone, while an agreement with Japanese conglomerate Marubeni Corporation also holds promise. For now, let’s explore what makes aluminium such a critical material.

Are environmental regulations, health and safety concerns or potential profit loss a concern right now?

What’s the big deal with Aluminium?

Aluminium is the versatile all-rounder of the metals world.

It also comes with several competitive advantages over its metallic rivals.

As the leading choice for sustainable product development, due to its low weight, strength, flexibility and infinite recyclability, Aluminium is in the box seat to benefit from the global drive to net-zero emissions.

Aluminium is used in many forms and can be submitted to an array of processes, including:

- Cast

- Melted

- Formed

- Machined, and

- Extruded

This variability allows aluminium to be manufactured into various shapes before getting fabricated to suit a wide range of uses.

It’s also only about a third of the weight of steel, making it easier and cheaper to transport than most other metals.

The six main benefits of aluminium over other metals are considered to be:

- The light weight

- Corrosion resistance

- Electrical & thermal conductivity

- Reflectivity and Ductility

- Odourless and Impermeable

- Recyclability

Next, let’s take a look at the clean aluminium smelting technology known as ELYSIS.

ELYSIS: Clean Aluminium Smelting

ELYSIS is a joint venture between three of the world’s leading organisations.

Rio Tinto, Alcoa, and, surprisingly, Apple have teamed up to tackle the production of emission-free Aluminium.

Based in Montreal, Canada, ELYSIS has received funding from its two R&D partners alongside $13m from Apple and $160m from Canadian government departments.

The program aims to expand the ELYSIS technology – which eliminates all greenhouse gases (GHG) from the aluminium smelting process – and commercialise it at scale.

In Canada, ELYSIS could reduce annual GHG emissions by 7 million m/t, the equivalent of 1.8 million cars on the road.

As legislation around carbon emission becomes tighter, producers and manufacturers worldwide must focus on decarbonising their supply chains and processes.

The ELYSIS technology offers a unique solution for significantly reducing the carbon footprint of many elements that make up our daily lives, including transportation, construction, electrical and consumer goods industries.

Summary

A partnership involving three of the world’s most prominent companies is bringing aluminium smelting into the net-zero era.

The technology, named ELYSIS, can produce carbon-free aluminium while only ejecting one byproduct – pure oxygen.

Competitors Rio Tinto and Alcoa have come together and, with the support of none other than Apple, will try to expand on and fully commercialise the technology.

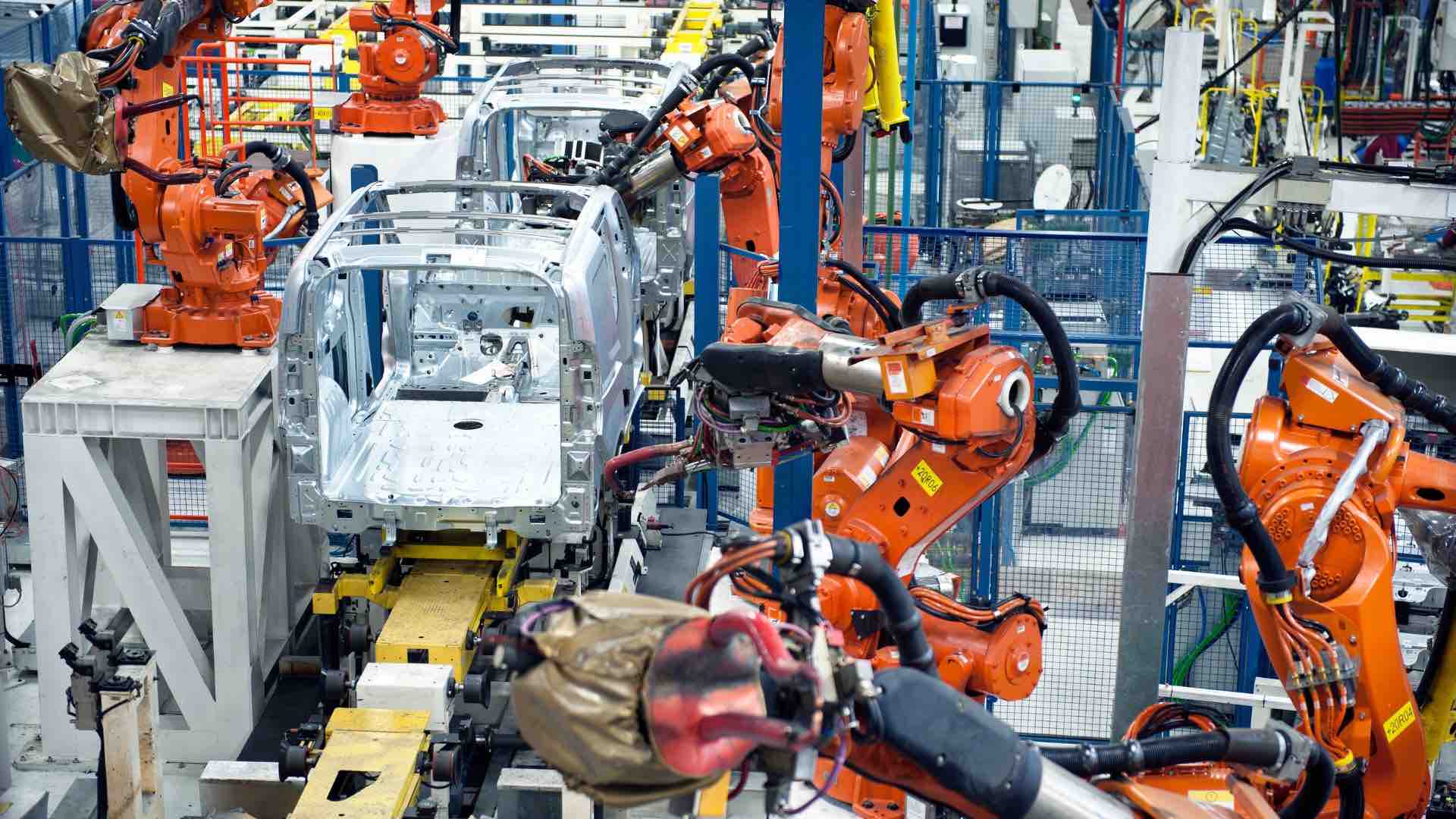

Rio and BMW have recently inked a supply deal for ELYSIS aluminium to be used in the manufacture of BMW’s premium vehicles.

Japanese conglomerate Marubeni Corporation has also secured a supply of carbon-free aluminium from the mining giant, with an eye on further expansion possibilities in the Japanese market.

Dust suppression is an enduring issue in the world of mining and energy.

Learn more about GRT’s industry-leading and IoT-connected SMART Dosing Units, and discover how we’re driving better dust suppression solutions for all!

Your feedback is important to us. If you enjoyed reading this Global Road Technology industry update and found it informative, please let us know by leaving a REVIEW.

References:

https://www.elysis.com/en/what-is-elysis

https://www.australianmining.com.au/news/wheels-turning-on-rio-tino-and-bmw-deal/

https://www.thyssenkrupp-materials.co.uk/advantages-of-aluminium.html