Introduction – Water Use in Mining

Over the years, Australia’s mining and resources industry has consistently been a key contributor to Australia’s economic growth, driven by mining exports. According to the Australian Bureau of Statistics (ABS), this contribution will continue to grow as Australia strengthens it’s mining and resources industry with renewable energy. Furthermore, as the global demand for mining commodities continues to increase, the need for effective, safe mining operations will indefinitely rise. While effective mining operations were previously reliant on innovative mining technology, the modern challenge exists in the area of dust control as the consequences of dust are affecting not only mining operations and equipment but also human health.

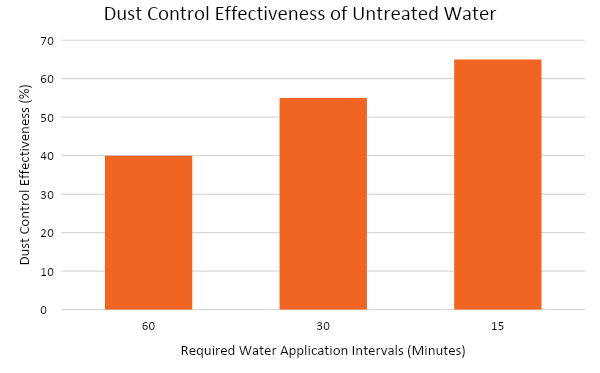

In the early 2000s, academics and mining practitioners alike identified a variety of different methods to combat the management of dust during mining operations. While these methods have included a variety of salts, surfactants, soil cements, bitumen, and polymer films, the most common dust control method to date is untreated plain water. This method typically requires a water truck to regularly apply untreated plain water on the common surfaces of the mining operations. While this method is effective in managing the dust and keeping the surfaces dust-free, academic studies have determined that watering once per hour only results in a dust control efficiency of about 40%. Increasing the application rate to every 30 mins or 15 mins will only increase the dust control effectiveness to 55% and 65%, respectively (seen in the figure below).

Water Alone Does Not Work!

Are environmental regulations, health and safety concerns or potential profit loss a concern right now?

With the dust control effectiveness of untreated water only at 40% for hourly applications, some mining sites around Australia have inevitably increased the rate of water application to every 30 or even 15 minutes, all to manage dust better. However, there are a variety of challenges and disadvantages associated with using water as a dust controller in Australia:

- Overwatering generates more dust on the wearing course of roads due to hydraulic pumping of fines from the body of the pavement to the surface.

- Potential water scarcity for regional centres located near Australia’s mining regions.

- Increased operating costs in all functions relevant to dust control (i.e. equipment cost, equipment repair, human resources, etc.).

- More water will be required as Australia’s increasing temperature results in the water drying out at a much faster rate.

- Increased traffic on mining roads resulting in a decrease in mining operation effectiveness.

- Increased environmental impact

The GRT Solution – GRT: Haul-Loc

To address the challenges and disadvantages of using water to manage and suppress dust during mining operations, the GRT engineering team have specifically formulated and designed dust suppression additives that not only addresses these challenges and disadvantages but also provide key benefits. For mining operations, the GRT: Haul-Loc provides these key benefits:

- Achieve dust suppression without overwatering the relevant surfaces. This improves the quality of the road and thus increases the life-span of mining vehicle tires.

- Immediate costs benefits compared to water alone.

- Long-term cost benefits from reduced windborne material loss.

- Improved health and safety on site – better visibility and reduced dust-related respiratory risks.

- Sustainable considerations – GRT: Haul-Loc is a sustainable product that provides environmental protection through being non-toxic, having a low carbon footprint, and reducing the damage caused by fugitive dust.

Access our free Mining Operations: GRT Haul-Loc calculator today!

GRT: Haul-Loc is an effective dust suppression and control product that can be applied to all types of mining operations. GRT: Haul-Loc’s effectiveness in controlling dust in mining operations has been documented in significant detail in a variety of GRT industry articles, including:

- Dust Suppression Methods in the Coal Mining Industry (March 2019)

- Is It Worth Controlling Dust with Water on Haul Roads? (February 2019)

- Managing Unsealed Pavements with Low or No Water Solutions (December 2018)

- Haul Road Wearing Courses – Unbound Mix Design (April 2016)

Further information regarding GRT: Haul-Loc can be found here.

Would you like to reduce operational costs, increase dust suppression at your site?

Contact Global Roads Technology Today!

We are an international leading, an engineering organisation that understands your need for effective operations whilst being cost-effective. GRT: Haul-Loc is a specially formulated liquid polymer that is effective in suppressing dust on haul roads. It is a cost-effective, environmentally friendly and designed specifically for the conditions of the mining and resource sectors.

GRT’s supply chains are secure with our mining products being proudly made in Australia.

Troy Adams

Troy Adams is the Managing Director of Global Road Technology (GRT) Specialising in Engineered Solutions for Dust Suppression, Erosion Control, Soil Stabilisation and Water Management. A pioneering, socially conscious Australian entrepreneur, Troy Adams is passionate about health and safety and providing innovative solutions that are cost-effective to the mining industry, governments and infrastructure sectors. Troy is also a tech investor, director of companies like Crossware, Boost, Hakkasan, Novikov and more.