Global Road Technology are silica dust control specialists servicing the mining, construction, renewables, quarrying and oil and gas industries. Dealing with silica dust at its source takes specific understanding of the particle size of silica dust in relation to the dust control product used. GRT has a range of different silica dust control products that can be utilized during activities such as drill and blast, tunneling, underground mining, stockpiling, transportation, haul roads, conveyor belt and transfer points amongst many other areas of application. Silica dust related terminology can be very confusing! There are must-know terms related to silica dust and these often find themselves being interchanged or misplaced in the thick of things.

In this article, GRT defines the following top 10 terms related silica dust:

Is a type of naturally occurring mineral that is made up of silicon and oxygen atoms to form silicon dioxide. It is widely abundant and it is the crystalline form of silica which is most commonly found as quartz. Different types of rock and rock products can contain different amounts of silica which makes the exposure to crystalline silica different depending on the type of rock and rock product. Granite (25 to 40%), Shale (22%), Natural sandstone (67%), Composite of engineered of manufactured stone (>90%) and Aggregates, mortar and concrete (various amounts).

Is a type of dust generated from stone containing silica from processes such as crushing, cutting, drilling, blasting, vehicular movements, material handling, and stockpiling amongst many others. The different silica dust particle sizes vary and some dust particles can be so small that they are not visible, which will be defined further with the term respirable. Silica dust can be in two different forms, namely crystalline or non-crystalline, the former causes irreversible lung damage whereas the latter does not cause that kind of lung damage. Silica is predominant in metalliferous dust, coal dust and asbestos dust which makes the term silica dust very source dependent.

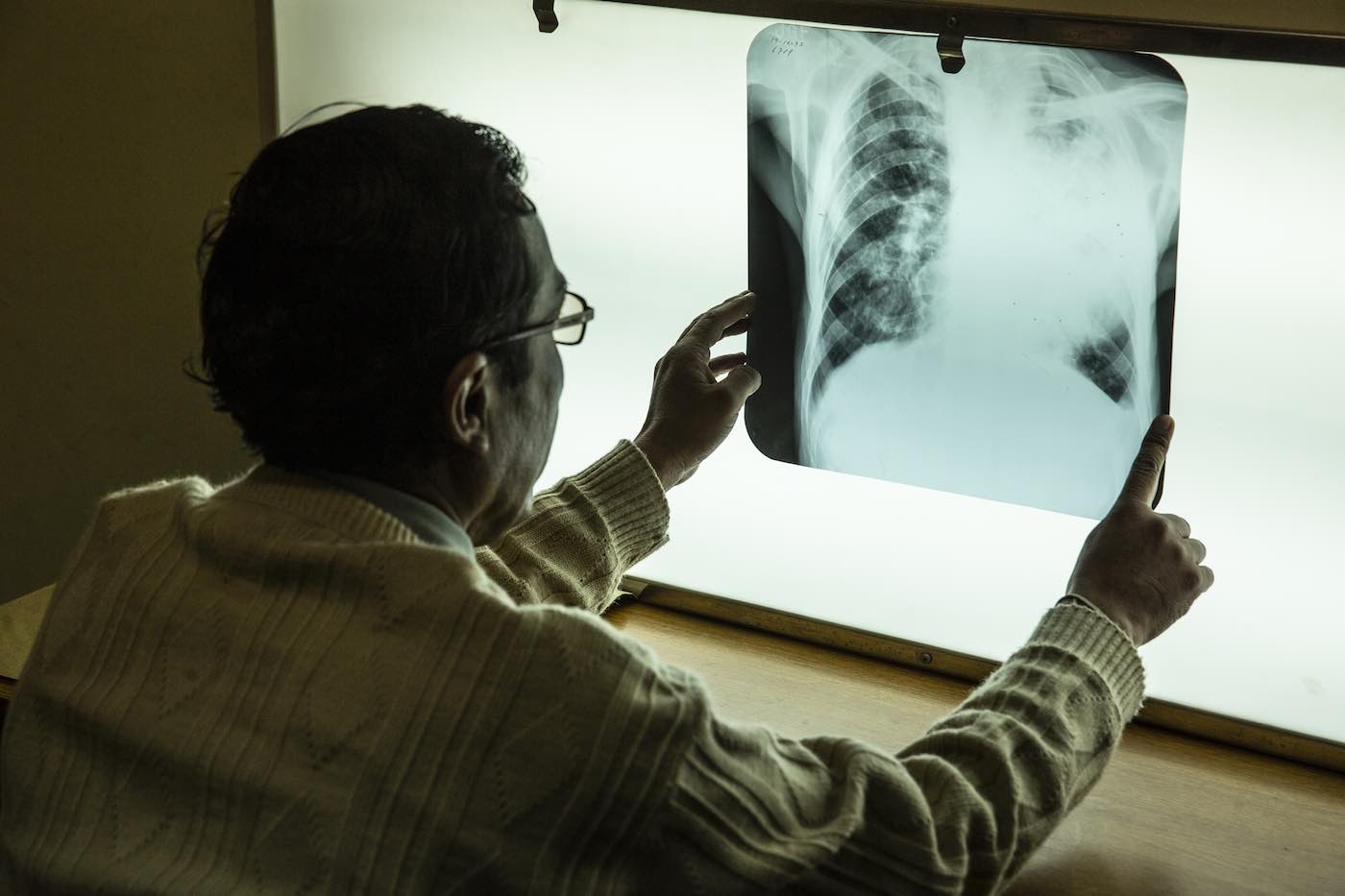

Is a group of diseases caused by exposure to and breathing in silica dust. It can be divided into three different types namely acute, accelerated and chronic silicosis. Acute silicosis can develop after a short exposure to very high levels of silica dust, within a few weeks or years and causes severe inflammation and an outpouring of protein into the lung. Accelerated silicosis can develop after exposures of 3 to 10 years to moderate to high levels of silica dust and causes inflammation, protein in the lung and scarring of the lung. Chronic silicosis can develop after long term exposure to lower levels of silica dust and cause scarring of the lung and shortness of breath.

Refers to the silica dust fraction that is hazardous when deposited anywhere in the gaseous exchange region of alveoli in the lungs. This respirable fraction of silica dust, is a sub-fraction of inhalable dust, covering all particles with an aerodynamic diameter of less than 4 microns with cuttings of about 10 microns.

Defines the fraction of silica dust that is hazardous when deposited anywhere in the respiratory tract. The size is relatively larger than the respirable fraction. This includes particles with an aerodynamic diameter of less than 100 microns.

This is another term used for the respirable fraction of silica dust which lodges in the alveoli region of the lungs. Its access to the deeper parts of the lungs is what makes respirable crystalline silica dust a serious hazard. Appropriate silica dust control measures must be taken to protect people from occupational and non-occupational exposure to respirable crystalline silica dust.

Are silica dust exposure limits set by regulatory agencies via a three-stage process of hazard identification, risk assessment and risk evaluation. They are numerical value which represent the exposure levels to which workers may be repeatedly exposed and are regarded as an acceptable risk. The consensus in values is amongst government representatives, health and safety professional, unions and employers. In Australia, WES for silica dust have recently been updated in the past 12 to 18 months with most of them halved from the previous values.

Is a chronic inflammatory lung disease that causes obstructed airflow from the lungs. Symptoms include breathing difficulty, cough, mucus production and wheezing. Its caused by long-term exposure to irritating particulate matter such as respirable crystalline silica dust. Emphysema and chronic bronchitis are two most common conditions that contribute to COPD.

Is ground-breaking technology to accurately monitor, record and store airborne silica dust levels data in real-time. This provides early detection of problematic areas, a trackable record of silica dust exposure and a better decision making tool which is backed up by data collected in real time. This method has been proven successful in accurately identifying the presence of silica dust and the Centre for Work Health and Safety in New South Wales, Australia are working towards having a commercially available model by March 2022.

Is the targeted use of dust control products such as liquid polymers, highly refined fluids and ionic surface active agents via a spraying systems to bind airborne silica dust particles and drop them to the ground-based on physicochemical interactions of the silica dust control method. Matching the particle sizes of the silica dust to the dust control product is pivotal to achieving successful silica dust control.

Find out more about silica dust in our latest GRT Q&A series interview with Steve Holland, Managing Director of airborne silica dust monitoring technology company, Trolex. For all your silica dust control requirements reach out to GRT General Manager, Daniel Grundy.

Your feedback is important to us. If you enjoyed reading this Global Road Technology industry update and found it informative, please let us know by leaving a REVIEW.

References

https://www.safeworkaustralia.gov.au/silica#the-workplace-exposure-standard

https://www.worksafe.qld.gov.au/search?query=workplace+exposure+standard

Are environmental regulations, health and safety concerns or potential profit loss a concern right now?

Contact Us Now