Press Release: November 3, 2022

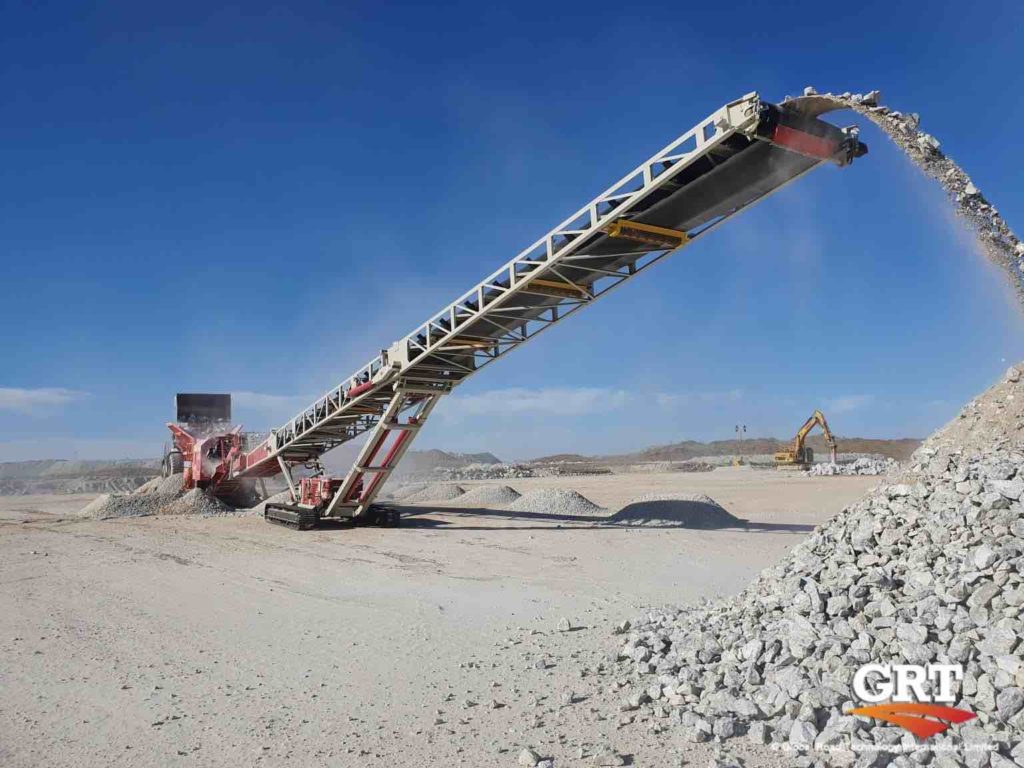

Leading mining and civil services firm Global Road Technology (GRT) is using its cutting-edge dust control technology to help combat the spread of crystalline silica dust across mining sites as pressure grows on Australian workplaces to meet higher safety standards as silicosis cases rise.

This growing pressure on employers follows the findings of the National Dust Diseases Taskforce in 2021 and a follow-up consultative process undertaken by Safe Work Australia on the Consultation Regulation Impact Statement: Managing the risks of respirable crystalline silica at work (CRIS).

According to GRT Managing Director Troy Adams, this evolving regulatory environment propelled the company’s significant investment into research and development to create their GRT: ACTIVATE products that suppress and strip out silica and coal dust caused by underground mining and tunneling operations, designed specifically for the resource and construction sectors.

“This growing pressure on industry to better manage the risk of silicosis will see whole of site’ dust mitigation strategies become a must for relevant workplaces,” said Mr Adams.

Are environmental regulations, health and safety concerns or potential profit loss a concern right now?

“Our ACTIVATE product range is designed to work in tandem to reduce the spread of particulate pollutants with GRT: 12X targeting the dust generated by exploration drilling and using the drills themselves to stop the fine dust caused by drilling by saturating it. The second prong is GRT: DC Binder, a polymeric additive that prevents hazardous airborne dust from being generated from the piles of fine Drill Cuttings (DC) by creating a tough surface crust that binds the hazardous dust particles in place – combined they can reduce the spread of hazardous material and protect workers.”

GRT is recognised nationally as an industry leader in dust control strategies, particularly in the mining, agricultural, and construction sectors. Its range of innovative products and techniques is designed to reduce the dust pollution generated by onsite industrial activity like drilling and stop it from spreading across the site and into local communities.

This approach is driven by it offering solutions at the apex of the hierarchy of control meaning that its products and techniques are designed to mitigate dust at its source to ensure that only minimal amounts of particulates reach workers – to the point where protective clothing and masks can safely deal with the remaining trace particles.

GRT’s innovative product suite of dust suppression non-toxic chemical applications twinned with its engineered dosing and application techniques has seen it emerge as a national leader in the development of infrastructure and process solutions for Australian industry.

GRT is releasing the ACTIVATE range at a time when the legislative environment across Australia is helping to drive better onsite management of dust pollution as major mining companies need to properly demonstrate that they are proactively reducing the spread of harmful airborne particulates.

“The re-emergence of silicosis is not only raising questions about the adequacy of the systems in place for the prevention, early identification, control, and management of this disease, but also in relation to broader occupational dust diseases,” Mr Adams said.

“Existing WHS regulatory frameworks are not effectively protecting people and there needs to be a more proactive approach from industry and government alike to collaborate on developing practical benchmark guidelines with the CRIS consultation process highlighting the need to have more than one control method. In response to this GRT recognises that its products are but just part of a mix of multiple methods of dust control implemented by the mining sector to provide adequate protection for workers.”

Source: AustralianMining

Troy Adams

Troy Adams is the Managing Director of Global Road Technology (GRT) Specialising in Engineered Solutions for Dust Suppression, Erosion Control, Soil Stabilisation and Water Management. A pioneering, socially conscious Australian entrepreneur, Troy Adams is passionate about health and safety and providing innovative solutions that are cost-effective to the mining industry, governments and infrastructure sectors. Troy is also a tech investor, director of companies like Crossware, Boost, Hakkasan, Novikov and more.

MORE INDUSTRY ARTICLES

Nothing found.