Dust monitoring devices measure different sizes and volumes of airborne dust particles. Measurements occur in different conditions through applying various measurement principles. The principles are light scatter forward, light scatter reversed, transmission and gravimetric analysis. The conditions are concentration, moisture, homogeneity, density, pressure, and process temperatures. Dust monitoring device test functions are automatic, manual and provide contamination checks. Then recording and precise measurement of dust and particle emissions is important. Dust particles generated at mines have significant impacts on humans and the environment – so dust monitoring should go beyond measurements alone. Mine workers, communities and the environment bear the effects of dust beyond measurement. There is no trade-off to health, worker safety and community safety. Monitoring is an important part of dust control practices, as it should drive actions that need to take place, but monitoring without action is basically pointless. This article discusses the problem, personal experiences and suggests solutions from a Global Road Technology perspective.

Why is dust a problem?

Dust consists of visible and invisible suspended and deposited solid particles. The grain size, geometric shape, surface characteristics shapes, and chemical compositions determine the properties and health effects of dust. Dust can also be defined as dispersed solid particles in the air generated by mechanical processes or resuspension. Examples of hazardous forms of dust are coal, asbestos, and crystalline silica dust. Exposure limits usually relate to acute and chronic health impacts. Dust monitoring devices measure dust. The problem is what happens beyond the measurement – i.e. what actions take place to manage the dust as overexposure to dust leads to health issues. This applies to workers, communities and the environment. Dust monitoring devices are good for the numbers. However, the effects of either side of the numbers needs to be dealt with at the source. Tackling dust at its source is the only form of defense against the effects of dust to humans and the environment. The approach goes beyond the measurement and conformity to set limits by the government. Understanding the factors in how chemical behavior of dust particles affects mine workers, communities and the environment is critical. The onus is on the industry to exercise the social license to operate and the duty of care. Dust management saves lives and the environment.

Behind every measurement is a person

Are environmental regulations, health and safety concerns or potential profit loss a concern right now?

Personal experiences refer to the resurgence of coal mine workers pneumoconiosis in Australia. In 2015, coal mine workers pneumoconiosis re-emerged in Queensland. The coal mining industry assumed the disease disappeared in the last half century. Evidence shows that the number of identified cases are more than those reported. In Queensland the legal limit for coal dust is 2.8 mg per cubic metre. 2014 recorded average coal dust levels were at 4.7 mg per cubic metre with extremes of 7 mg per cubic meter. Standards compliance enforcement belongs to the Queensland Department of Natural Resources. Exposure is exposure regardless of the location of the mining activity. Misconceptions drove the numbers of black lung disease to escalate. The associated risks taken for granted lead to less frequent health checks. The reemergence of coal mine workers pneumoconiosis serves as one personal reminder and experience. What are the benefits of measurement with little to no action? A focus on dust control rather than dust monitoring would have yielded different results and dust coal mine workers pneumoconiosis would be a relic of the past. The integrity of dust measurement alone as 2014 was questionable. All the red flags pointed towards looming health disaster in Queensland.

Dust impacts on the community

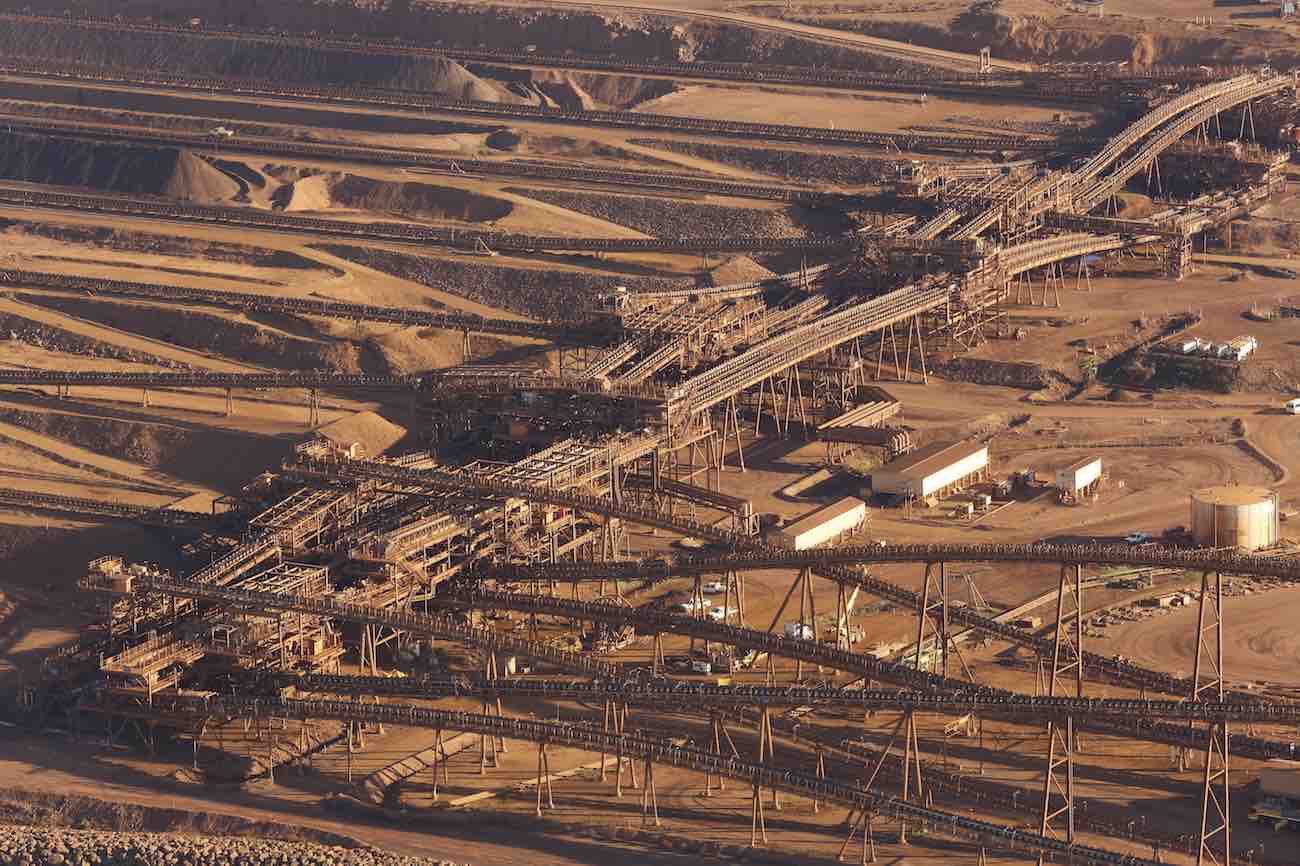

A recent news article shared how a mother-of-two contracted silicosis from a nearby quarry in Australia. Around 6% of all Australians get exposed to crystalline silica dust each year. Failure to control dust at its source results in health problems outside the quarry which affects the community. Quarry owners must put in place dust control measures which suppress dust at its source. Our quarry dust control article tackles worker health and safety but unfortunately it is extending beyond the quarry into the community. Really there is never a safe level of exposure to crystalline silica. Standard 8-hour shift exposure limits for Australia are between 0.05 and 0.1 milligram per cubic metre. The different types of quarries are natural stone quarries and rock aggregate quarries. Majority of dust generation is from drilling at natural stone quarries. Rock aggregate quarries produce aggregates of various sizes through crushing and sieving. Rock detachment from the bedrock happens via drilling and fed into a crusher feeding bin. Larger rocks are fragmented with a hydraulic impact hammer before crushing. Bulk of the dust comes from crushing and sieving. Drilling and blasting contribute to dust emissions as well. Dust control measures employed include water and other water applications. Are water dust control measures adequate? The recent silicosis surge shows that water does not work. What works then?

Examples of industry best practice

Engineered solutions that target the elimination of dust at its source is what works. How can it be achieved? Well, it starts from understanding the type of dust to be suppressed. For example, coal and silica dusts are extremely hydrophobic – meaning water hating or repelling. Using water to suppress coal dust is ineffective. Global Road Technology has developed with viable solutions for coal and silica dust suppression. Given the chemistries of crystalline silica dust, it is key to use a product, which has hydrophobic and hydrophilic properties. GRT Activate super-activates water which increases efficacy in coal dust suppression. Formulated for the coal face and also used to manage coal dust from large mineral stockpiles, conveyors or any fine minerals in transit. GRT Activate also enables water to sequester and bind crystalline silica from mineral aggregates. This reduces the repulsion of fine dust particles to use of water alone.

Dust Monitoring vs Dust Management

So what can we say in conclusion – dust-monitoring devices assist in compliance but must lead to dust management actions. Monitoring can’t be the standard that we hold industry to – even if “we” might penalize them with fines for exceedances. Measurable dust management behaviours and actions is where we need our industry legislation and standards to move towards – it is a life and death situation.

Your feedback is important to us. If you enjoyed reading this Global Road Technology industry update and found it informative, please let us know by leaving a REVIEW.

REFERENCES

- Australian Standard. 2009. Workplace atmospheres-Method for sampling and gravimetric determination of inhalable dust.

- Australian Standard. 2009. Workplace atmospheres-Method for sampling and gravimetric determination of respirable dust.

- Belle, B. 2017. Pairwise evaluation of PDM3700 and traditional gravimetric sampler for personal dust exposure assessment. The Australian Mine Ventilation Conference. Brisbane, QLD.

- CDC Workplace Safety and Health. 2003. Handbook for Dust Control in Mining. Department of Health and Human Services.

- Cheriyan, D., and Choi, J. 2020. Estimation of particulate matter exposure to construction workers using low-cost sensors. Sustainable Cities and Society. 59:102197. 1-12.

- DustTrak II. Retrieved 13/02/21

- Ren, T.X., Plush, B., and Aziz, N. 2011. Dust Controls and Monitoring Practices on Australian Longwalls. Procedia Engineering. 26. 1417-1429.

- SICK Sensor Intelligence. 2000. Dust Measuring Devices. Retrieved 13/02/21

- Thakur. P. 2019. Health Hazards of Respirable Dusts. Advanced Mine Ventilation. Book Chapter.

- Thakur. P. 2019. Respirable Dust Sampling and Measurement. Advanced Mine Ventilation. Book Chapter.

Troy Adams

Troy Adams is the Managing Director of Global Road Technology (GRT) Specialising in Engineered Solutions for Dust Suppression, Erosion Control, Soil Stabilisation and Water Management. A pioneering, socially conscious Australian entrepreneur, Troy Adams is passionate about health and safety and providing innovative solutions that are cost-effective to the mining industry, governments and infrastructure sectors. Troy is also a tech investor, director of companies like Crossware, Boost, Hakkasan, Novikov and more.