Press Release: 31 August 2022

From autonomous haulage systems to the electrification revolution, investment in new technology is helping companies push the boundaries.

Whether in mining, manufacturing, agriculture or renewable energy, advances in automation are accelerating product development in different applications.

Mining companies are constantly searching for innovative solutions that drive cost efficiencies, boost productivity, and maximise equipment life, whilst improving safety and maintaining strict sustainability agendas.

The demand for more sophisticated hardware and connectivity is becoming increasingly prevalent in the continuous improvement of haul road dust suppression to tackle challenges related to obstacle detection and collisions when autonomous mine trucks are in operation.

The application of dust suppression systems is critical in mining and resources, civil construction, agriculture, and environmental management. Companies need to be actively developing new products and solutions that improve the way in which they manage environmental issues onsite.

Are environmental regulations, health and safety concerns or potential profit loss a concern right now?

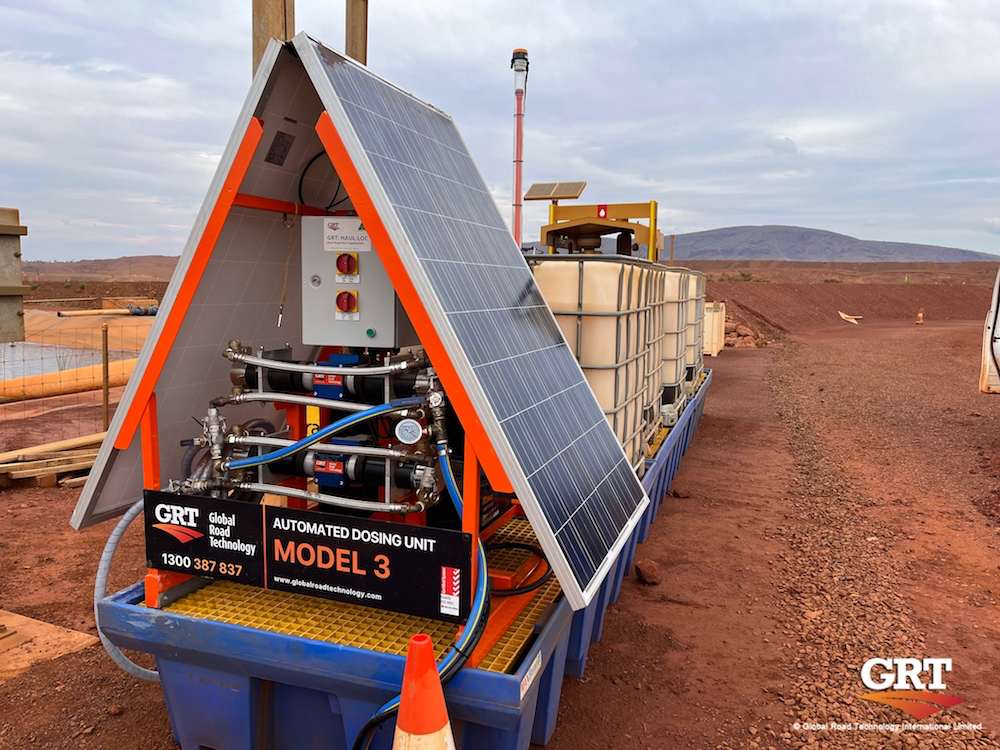

Global road technology (GRT) is one company leading the automation race with the launch of its smart (sustainable, mine, autonomous, reporting, technology) dosing units, which have become a game changer in mine water management and dust suppression.

GRT has invested heavily in the automation of their dust suppression products for both above-ground and underground operations. These products support mining companies in keeping their workers and surrounding communities safe.

Smart automation in dust suppression

GRT SMART Dosing Units are the key hardware component of its industry-leading dust suppression systems offering the most effective haul road management and dust control.

Designed and assembled by GRT’s engineers, these Australian-made SMART Dosing Units consist of a central control and communication module combined with electrical and mechanical hardware that allows remote control and automates product dosage, error detection, and flow rates using the internet of things (IoT) technology.

According to GRT Managing Director, Troy Adams, the investment in automation is intended to provide resource companies with a turnkey dust control solution that protects onsite workers and communities located nearby.

“Our products are designed to stop the spread of dust particles generated by mining activity and the smart dosing units take it to the next level by using data and automation to improve dust control outcomes,” said Adams.

“GRT’s dosing units have the capability to utilise both 5g and satellite with the preference of the latter which enables remote management and communication with the remote-operations control centre of the mine.”

“We have designed products like GRT: Haul-Loc and GRT: Activate that dovetail into these autonomous systems, to deliver effective dust control and provide critical data currently missing onsite.”

GRT’s significant investment in R&D and innovation, combined with specialist expertise in dust control, soil stabilisation, erosion control, and water management, has reinforced its reputation as a global leader in dust suppression in mining and construction.

Environment driven innovation

The evolving legislative landscape in Australia has led to the widespread adoption of rigorous sustainability agendas by mining companies globally.

Increased awareness of the health risks linked to dust pollution and growing community pressure are driving action in the industry. Airborne dust pollution and dust-related lung disease such as silicosis are at the top of the list for companies as they face pressure to be more proactive in reducing the onsite spread.

A critical point of difference with GRT’s SMART Dosing units is the use of technology to help them effectively deal with the issue of airborne dust.

“In addition to accurately dosing our dust control products, our latest smart dosing units include telemetry, which acts as a data hub and enables direct reporting, tracking, and dosage control, all within a user-friendly app interface,” said Adams.

“This powerful data includes water consumption, water truck operational efficiencies, product levels, dosage rates and the overall effectiveness of the supporting gear such as pumps and power units that provide these services.”

“This offering is designed to replace traditional water-based methods or outdated dust control chemicals employed by miners to manage dust for us the smart product suite further showcases where we can go as a sector.”

GRT’s dust control, soil stabilisation, erosion control and water management solutions have been designed with both end-user applications and the environment in mind.

From underground mines seeking to protect workers from dust-related health issues to resource companies in need of durable access roads all year round to military personnel requiring all-weather, dust-free campgrounds, to farmers protecting cattle and horses, to construction sites preventing erosion you can be assured GRT’s Solutions will achieve the required outcomes.

GRT: 12X is the latest example of the company’s relentless pursuit to design products that protect workers. It has been independently verified by Australia’s leading universities to be 12 times more effective than water alone in suppressing coal dust and other fine dust.

Its innovative product range has been formulated in world-class laboratories and tested in the toughest environments, helping companies create safer, more reliable, and resilient operations.

More information on GRT SMART dosing units and dust suppression solutions for the mining industry is available on our website.

Source: Australian Mining Review

Troy Adams

Troy Adams is the Managing Director of Global Road Technology (GRT) Specialising in Engineered Solutions for Dust Suppression, Erosion Control, Soil Stabilisation and Water Management. A pioneering, socially conscious Australian entrepreneur, Troy Adams is passionate about health and safety and providing innovative solutions that are cost-effective to the mining industry, governments and infrastructure sectors. Troy is also a tech investor, director of companies like Crossware, Boost, Hakkasan, Novikov and more.

MORE INDUSTRY ARTICLES

Nothing found.