What explosives are used in rock blasting? – Collectively, explosives used to break rocks are known as fracture explosives which distinguishes them from accessories such as detonators and others used to initiate a blast in a controlled manner. They are detonable substances or devices that produce a high-intensity shock wave and large volumes of gas which, being confined in a hole, expand rapidly, entering existing minor cracks in the rock, and creating new cracks to break the rock. Mining is the largest consumer of civil explosives including other rock blasting applications such as quarrying and tunnelling. Gunpowder also known as black powder was the first generation of explosives used in all applications. About 1000 years ago, the Chinese invented these explosives, with the first European sources manufactured by the Germans in the early 1300s. Let us broaden our scope to detonators, these are devices used to trigger these explosives in rock blasting. Detonators can be chemically, mechanically, or electrically initiated. Different explosives require different amounts of energy to detonate. Detonation is a necessity for the explosive to get triggered for rock blasting. Explosives are an essential part in the overall fragmentation system of a mine cycle and blasting technology has become an art involving use of calculated number of explosives to yield a predetermined volume of rock material broken down into pieces. This article focuses on types of explosives used, chemistry of explosives, technical aspects of blasting and selection of explosives used in rock blasting.

A view from history to the present use of ANFO.

Explosives are classified into low and high explosives. Low explosives were the earliest to be developed. These lead to an explosion which is really a rapid form of combustion in which the particles burn at their surfaces and expose more and more of the bulk until all is consumed. An example is black powder which is commonly known as gunpowder. It is mixture of potassium nitrate, sulphur and carbon in the form of charcoal. In the 19th century, the invention of dynamite by the Swedish chemist and engineer Alfred Nobel gained popularity. Dynamite is an explosive made of nitroglycerin, sorbents such as powdered shells or clay and stabilisers. In essence, dynamites gained popularity owing to its wide-scale use as a safer alternative to gun powder and nitroglycerin alone. Since then, a wide variety of nitroglycerine-based explosives have been produced. Although, they have high detonation velocities and good water resistance, they have high flammability, are highly sensitive to shock and friction and produce large noxious fumes. The most commonly used explosive in mining globally is ammonium nitrate fuel oil (ANFO). It was introduced for blasting operations in the 1950s. Chemically, ANFO is ammonium nitrate mixed with fuel and proper mixing of AN and FO is important for predictable explosive performance.

Chemistry of explosives – ideal reactions and deviations from normal reactions.

AN is stable at ambient temperature, but can absorb moisture from the atmosphere if the humidity is above 60%. Anti-caking agents minimise moisture absorption and caking. While it supports combustion, AN is not flammable, however it is an oxidiser. An ideal reaction to make ANFO must consist of 94.5% AN and 5.5% FO to yield nitrogen, carbon dioxide, water and a maximum energy output. The oxygen balanced reaction and none of the detonation products are poisonous. On the contrary, a mixture containing of 92% AN and 8 % FO creates oxygen deficiency. As a result, the carbon in the mixture is oxidised only to carbon monoxide, a poisonous gas, rather than relatively harmless carbon dioxide. Some of the nitrogen from the AN reacts with excess oxygen to form nitrous oxide which, upon exposure to normal atmosphere, forms NO2, a toxic gas. Preference for the oxygen balanced reaction is to maximise energy release while minimising the formation of toxic gases.

Are environmental regulations, health and safety concerns or potential profit loss a concern right now?

Addition of aluminium powder to ANFO increases the energy yield, the higher heat of explosion is due to the high heat of formation of aluminium trioxide. The application of AN extends to slurry and emulsion type of explosives. A slurry explosive is a mixture of AN and sodium nitrate, a fuel sensitiser such as carbonaceous fuels, explosive or non-explosive with varying amounts of water. Emulsion explosives have the oxygen donor consisting of nitrates and perchlorates in an aqueous solution. The explosive is sensitised by gas bubbles in the form of microspheres and there are different types known as straight, doped and re-pumpable emulsions. The applications of using AN vary from dry to wet but the common chemical constituent is ammonium nitrate. A good combination of slurry, emulsion and ANFO is Heavy ANFO which has advantages of both the high density and water resistance of slurries and emulsion plus low cost of ANFO.

Technical aspects of blasting – techniques and devices.

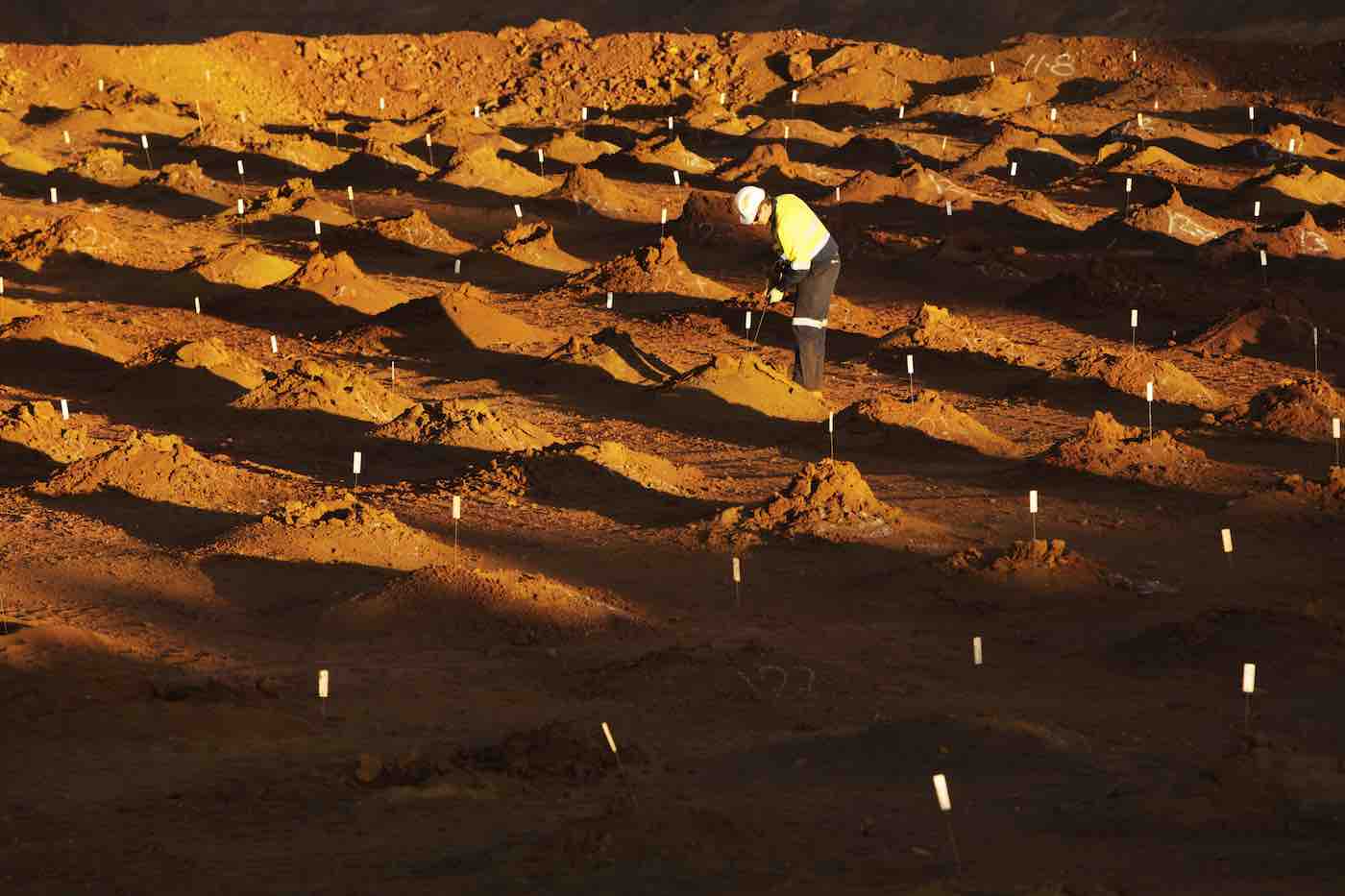

The properties of interest in selecting rock blasting explosives includes strength, measured against various standards such as density, sensitivity to initiation, water resistance and Velocity Of Detonation (VOD). VOD is key for achieving the speed at which an explosion propagates along a blasthole and is crucial for the functioning of explosives. Under ideal conditions, ANFO has a VOD of about 4400 m/s. Initiation systems have also evolved over time. For many years, explosives were initiated by fuse and ignitor cord which have a known range of burning speed, allowing miners to time the sequence of individual charges, however it had very low accuracy. A fuse with a detonator at one end (capped fuse) enables both fuse and ignitor cord to burn under water. Various types of instantaneous and delay electric detonators have now been in use for many years up to the present. They may be initiated by electric current from main firing devices or from small portable devices called shot exploders. They vary in capacity which is the number of detonators that they are capable of initiating. Various combinations of series and parallel firing circuits are used.

In the interest of safety and efficiency, the preferred modern method of initiating blasts is by shock tube, non-electric detonators capable of extremely accurate timing, although they are themselves normally set off by a single electric detonator. Detonating cord is a strong, robust, elongated tube of plastic-coated explosive material which is fed into holes to detonate fracture explosives and it can have VOD of about 7000 m/s. In many cases, a detonator is insufficient to ensure effective detonation of explosives in a blasthole. A primer, which is a cartridge of high energy explosive into which a detonator is inserted, is used to initiate the detonation of a column of explosives in a blasthole. Boosters may be used, with one or more additional high-energy cartridges placed at intervals along a hole to increase VOD. Containment of energy of explosives in a blasthole is achieved through tamping or stemming which is a plug of inert material such as sand or mud, placed near the mouth of the blasthole. Decking is then the practice of placing plugs of inert material at intervals along a hole to limit energy concentration.

Blast design criteria

We conclude with the selection criteria of explosives used in the rock blasting. These include critical diameter of blasthole, hydrostatic pressure, temperature, minimum primer weight, density weight strength, bulk strength, gap sensitivity, water resistance, loading procedures, coupling or decoupling properties, shelf life, reliability for bulk operations and overall drilling and blasting economics. As can be seen, blast design, planning and successful blast outcomes depends on many factors.

Your feedback is important to us. If you enjoyed reading this Global Road Technology industry update and found it informative, please let us know by leaving a REVIEW.

REFERENCES

Bhandari, S. 1997. Engineering Rock Blasting Operations. A.A. Balkema, Rotterdam. Netherlands.

Extractives Hub. 2021. Technical Aspects of Mining. Retrieved 24/04/21

Troy Adams

Troy Adams is the Managing Director of Global Road Technology (GRT) Specialising in Engineered Solutions for Dust Suppression, Erosion Control, Soil Stabilisation and Water Management. A pioneering, socially conscious Australian entrepreneur, Troy Adams is passionate about health and safety and providing innovative solutions that are cost-effective to the mining industry, governments and infrastructure sectors. Troy is also a tech investor, director of companies like Crossware, Boost, Hakkasan, Novikov and more.